Containerized RO Systems – CBR Series

CBR & CSR Series – Modular Containerized RO Systems

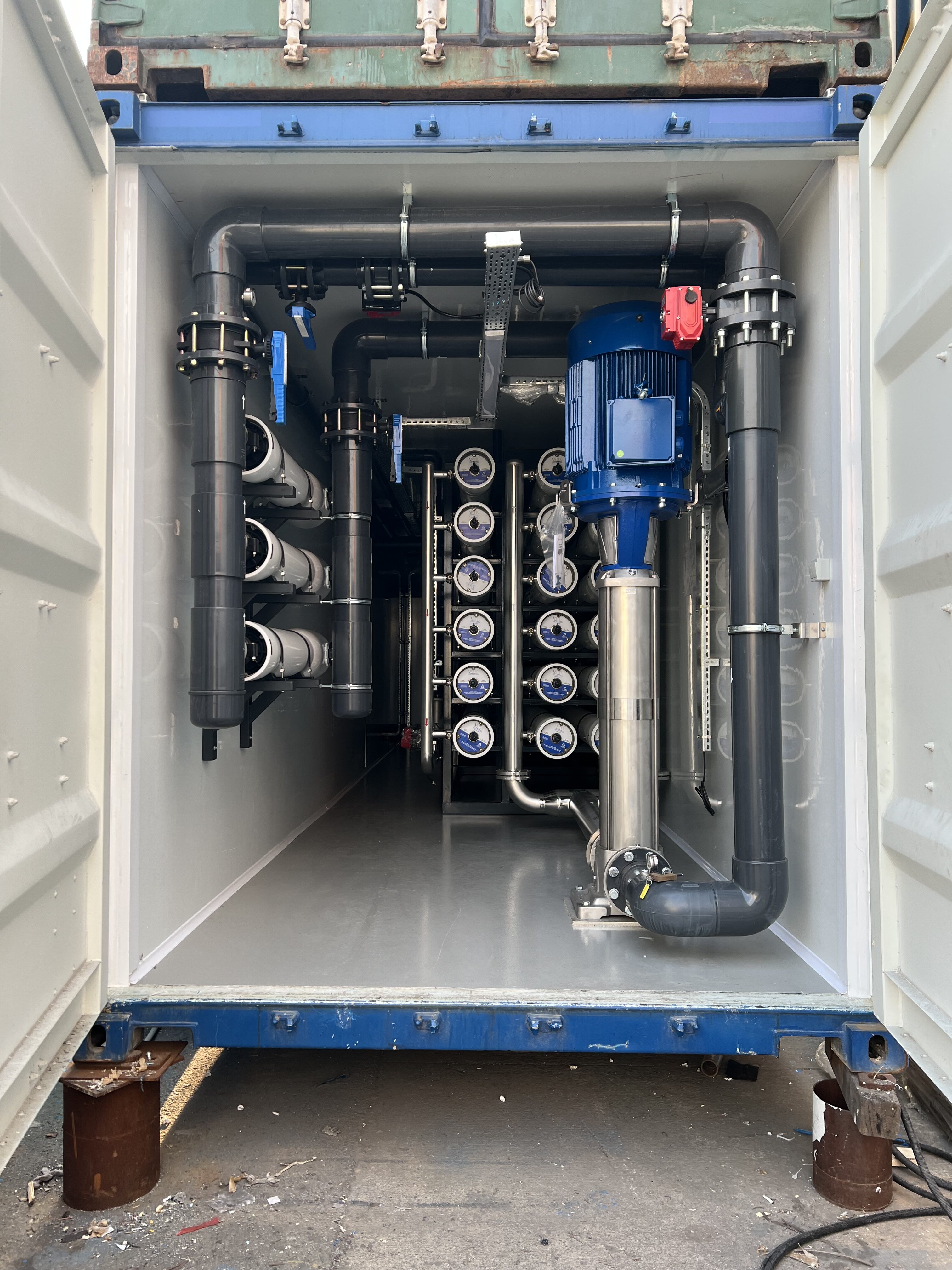

TRIWA’s CBR and CSR Series are advanced, containerized reverse osmosis (RO) systems built for reliability and flexibility. Each plug-and-play unit delivers 250 to 3,000 m³ of clean water daily from brackish or seawater, even in challenging environments. Featuring modular scalability, smart automated controls, energy-efficient operation, and marine-grade durability, these ISO-certified systems are ideal for rapid deployment at remote sites, construction projects, power plants, emergency relief, and industrial applications.

- Categories: Modular Water Treatment Plants, Purification

Description

CBR™ Series – Modular, Plug & Play Solution for Brackish & TSE Polishing

Brackish Water Containerized RO systems are designed for efficient and reliable purification of brackish water and TSE polishing. The CBR™ series is packaged in durable, weather-resistant shipping containers for easy transportation and installation—ideal for remote locations and areas with limited space.

Key System Features

Modular & Scalable Start small and grow smoothly from 250 to 3,000 m³/day. Additionally, link units to reach 20,000 m³/day.

Automated & Remote Smart PLCs, precise sensors, and automated valves reduce manual work. Remote access lets you monitor and control the plant anytime, anywhere—keeping performance stable and reliable.

High Recovery & Low Energy The design targets up to 85% recovery with low energy demand. Low-pressure membranes and efficient hydraulics help keep power use and OPEX down.

BWRO Models

- CBR-500: 500 m³/day

- CBR-800: 800 m³/day

- CBR-1000: 1,000 m³/day

- CBR-1500: 1,500 m³/day

- CBR-2000: 2,000 m³/day

- CBR-3000: 3,000 m³/day

Typical Equipment Selection

| Equipment | Included | Optional |

|---|---|---|

| Auto Screen Filter | ✓ | |

| Pre-Chlorination Dosing | ✓ | |

| Multi Media Filters | ✓ | |

| Activated Carbon Filter | ✓ | |

| SMBS Dosing | ✓ | |

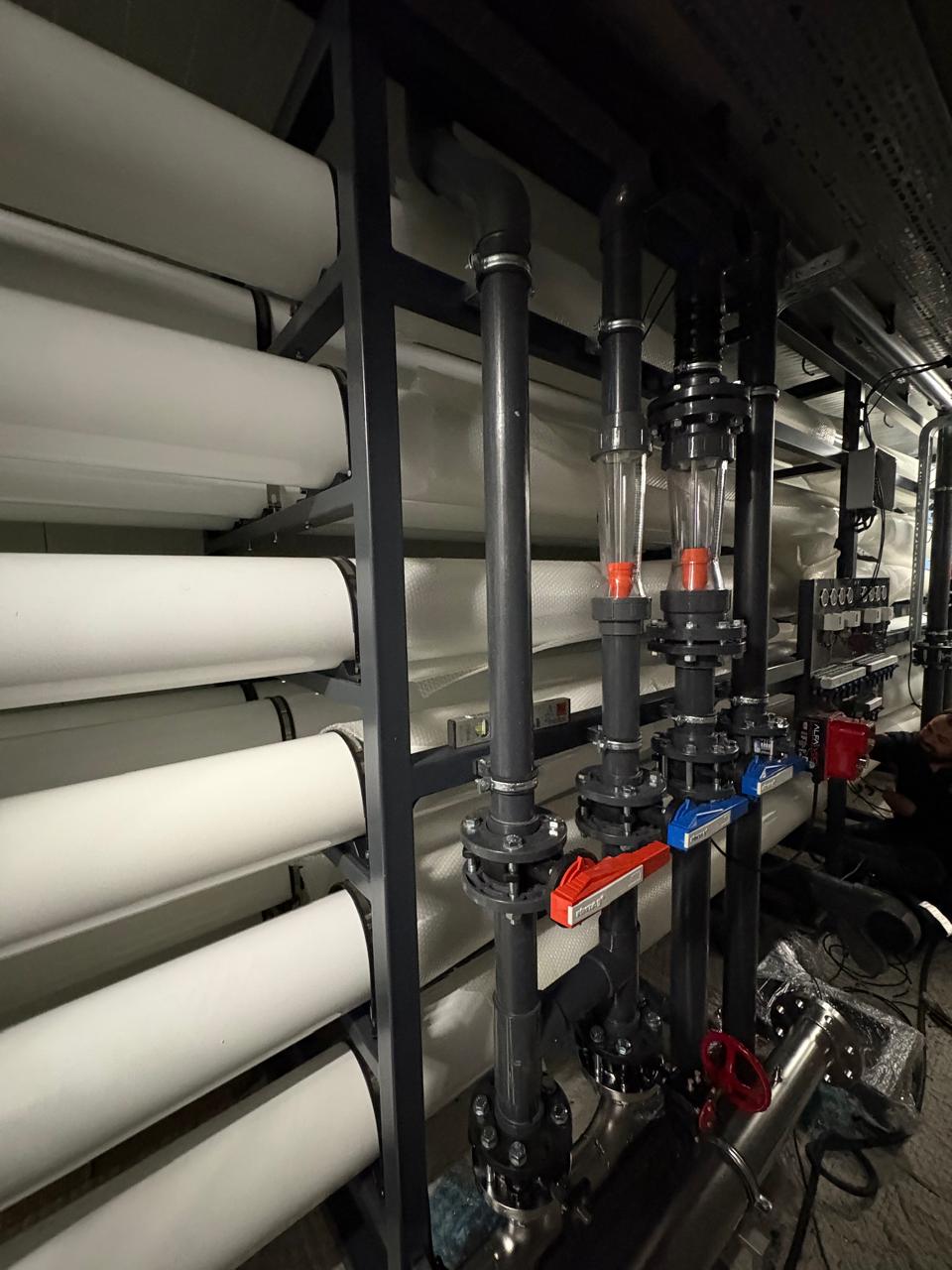

| Micro Filtration | ✓ | |

| Anti Scalant Dosing | ✓ | |

| High Pressure Pump | ✓ | |

| Reverse Osmosis Rack | ✓ | |

| Instrumentation (TDS, ORP, pH, Flow, Pressure) | ✓ | |

| Centralized PLC & MCC Panel incl. HMI | ✓ | |

| Remote GSM Module | ✓ | |

| Post Chlorination Dosing | ✓ |

Configurations

| Model | Typical Daily Capacity (m³/day) | Footprint (Container) |

|---|---|---|

| CBR-500 | ~500 | 40′ |

| CBR-800 | ~800 | 2 × 40′ |

| CBR-1000 | ~1,000 | 2 × 40′ |

| CBR-1500 | ~1,500 | 2 × 40′ |

| CBR-2000 | ~2,000 | 2 × 40′ |

| CBR-3000 | ~3,000 | 3 × 40′ |

Typical Design Basis

| Raw Water Parameters | BWRO | Unit |

|---|---|---|

| TDS | < 2500 | ppm |

| Temp | 25 | c |

| Treated Water Parameters | BWRO | Unit |

|---|---|---|

| TDS | < 150 | ppm |

| Temp | 25 | c |

*Feed & product water quality shall be finalized based on customer inlet water analysis.

Why Choose CBR™?

- Plug-and-play brackish water RO systems built for reliable, efficient service (clean water from wells, boreholes, or similar sources).

- Pre-assembled and ISO-certified for fast deployment with minimal site work—ideal for remote, industrial, or temporary sites.

- Modular growth from 250–3,000 m³/day, with multi-unit linking up to 20,000 m³/day.

- Smart automation + remote access to monitor/control anytime, anywhere—stable daily performance.

- High recovery (up to 85%) and low energy demand to reduce power consumption and OPEX.

In summary, CBR™ is a containerized BWRO platform for brackish water and TSE polishing—fast to deploy, easy to scale, and engineered for stable performance with automation and high-recovery efficiency.