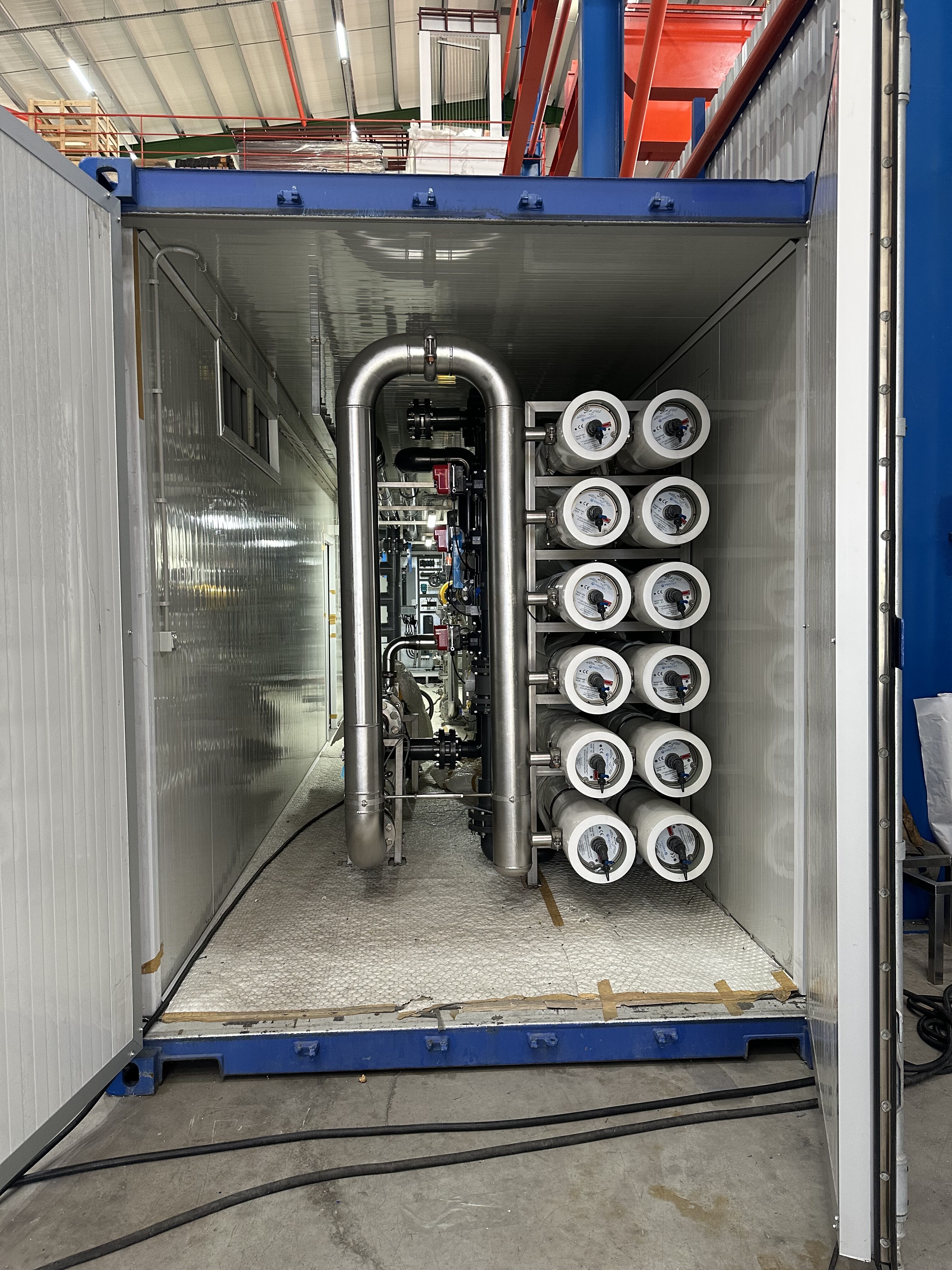

Containerized RO Systems – CSR Series

CSR Series – Modular Containerized SWRO Systems

TRIWA’s CSR Series are advanced, containerized seawater reverse osmosis (SWRO) systems designed for exceptional reliability and performance in marine and coastal environments. Each plug-and-play unit delivers 250 to 2,000 m³/day of high-quality freshwater from seawater sources. Moreover, every system is fully pre-assembled, ISO-certified, and ready for rapid deployment with minimal site work. As a result, the CSR Series is ideal for islands, coastal communities, marine platforms, resorts, and emergency desalination operations across Saudi Arabia and the wider Gulf region.

Built for scalability and long-term efficiency, the CSR range integrates smart automation, remote monitoring, PX or turbo energy recovery, and marine-grade materials such as SS316L and FRP. Therefore, each system ensures reliable operation, lower maintenance, and sustainable water production—whenever and wherever it’s needed.

- Categories: Modular Water Treatment Plants, Purification

Description

SWRO Models

- CSR-800: 800 m³/day

- CSR-1000: 1,000 m³/day

- CSR-1500: 1,500 m³/day

- CSR-2000: 2,000 m³/day

Capacity range: 800–2,000 m³/day. Customization is available based on project requirements.

Typical Equipment Selection

The table below reflects a typical CSR™ equipment scope (included vs optional). Final configuration can be tailored to inlet-water analysis and client specs.

| Equipment | Included | Optional |

|---|---|---|

| Auto Screen Filter | ✓ | |

| Pre-Chlorination Dosing | ✓ | |

| Multi Media Filters | ✓ | |

| Activated Carbon Filter | ✓ | |

| SMBS Dosing | ✓ | |

| Micro Filtration | ✓ | |

| Anti-Scalant Dosing | ✓ | |

| Acid Dosing | ✓ | |

| High Pressure Pump | ✓ | |

| Energy Recovery Device (Turbo or PX) | ✓ | |

| Reverse Osmosis Rack | ✓ | |

| Instrumentation (TDS, ORP, pH, Flow, Pressure) | ✓ | |

| Centralized PLC & MCC Panel incl. HMI | ✓ | |

| Remote GSM Module | ✓ | |

| Post-Chlorination Dosing | ✓ |

Want a tailored scope? We can align pretreatment, dosing, and monitoring options to your inlet-water profile.

Configurations

| Model | Typical Daily Capacity (m³/day) | Footprint (Container) |

|---|---|---|

| CSR-800 | ~800 | 2 × 40′ |

| CSR-1000 | ~1,000 | 2 × 40′ |

| CSR-1500 | ~1,500 | 2 × 40′ |

| CSR-2000 | ~2,000 | 3 × 40′ |

Typical Design Basis

| Raw Water Parameters | SWRO | Unit |

|---|---|---|

| TDS | < 40,000 | ppm |

| Temp | 30 | °C |

| Treated Water Parameters | SWRO | Unit |

|---|---|---|

| TDS | < 500 | ppm |

| Temp | 30 | °C |

*Feed & product water quality shall be finalized based on customer inlet-water analysis.

Why Choose CSR™?

- Plug-and-play deployment: Pre-assembled, containerized solution for fast installation and minimal site work.

- Built for coastal & remote sites: Designed for reliable operation in marine/coastal environments and space-limited locations.

- Smart automation: PLC control with precision sensing and automated valves supports stable daily performance.

- Lower running cost: Energy recovery (PX/turbo) reduces power consumption and improves lifecycle economics.

Need sizing support? Share your inlet-water analysis and target output specs, and we’ll recommend the best CSR™ configuration.

“`